The company Beissbarth has been active in the automotive industry for over 123 years, developing innovative testing and service equipment in the premium segment. One essential area of the Beissbarth portfolio focuses on the wheel alignment of vehicles. In 2021, the company introduced Q.Lign, a product that offers significant service potential for automotive workshops by enabling precise wheel alignment.

The components of a vehicle's suspension system and tires are constantly subjected to extreme forces caused by torque and weight, and without regular adjustments, excessive wear and tear are inevitable

New: Q-Lign T-Series as an off-the-lift solution

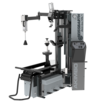

The new Q.Lign T-Series wheel alignment system helps workshops to fully tap into this service potential. Building on the success of the innovative Q.Lign electronics and software platform, the T-Series expands Beissbarth's wheel alignment range with a standalone off-the-lift solution.

What’s new? Instead of being mounted on the side of the lift, four cameras are mounted at a height of 2.8 meters in front of the vehicle. The special design of the cameras allows measurements to be taken from a distance of 1.8 to 3.3 meters from the front axle, without requiring any height adjustment, regardless of the length of the wheelbase. Motors, winches, and constant up-and-down movement of the wide camera beams are now a thing of the past.

Q.Lign and Q.Lign T-Series complement each other perfectly

This is made possible by the deliberate design of two cameras on each side. While a wide-angle camera monitors the area around the front axle, a second camera can fully focus on the rear axle - thus covering a wide range of vehicles from small cars to long transporters.

Every wheel alignment expert knows that the rear axle determines the toe values on the front axle. The better you can determine the rear axle, the higher the accuracy of front toe settings. Even the first version of Q.Lign dedicates one camera to each wheel in order to get the maximum performance for every possible vehicle configuration. Conventional two-camera systems, on the other hand, have to capture and measure both the rear and front axle simultaneously with only one camera.

Software processes, functions, measurement panels, as well as the proven Stream-to-X technology that allows access to measurement data or protocols from anywhere in the workshop, are continued 1:1 with the T-Series.

In addition to their different measuring positions and camera setups, Q.Lign and the Q.Lign T-Series differ in one important point: While Q.Lign integrates wheel alignment and ADAS calibration into one procedure, the new T-Series focuses on workshops with dedicated wheel alignment workstations, and is located in front of the vehicle..

Thanks to the Q.Lign platform, the traditional trolley is completely eliminated in both solutions. This means that the T-Series can also be mounted on the wall to save space and make the lift 360° accessible.

Q.Lign T-Serie available in two versions

The Q.Lign T-series will therefore be available in two versions: Mounted on a column in front of the vehicle or as a wall-mounted solution.

- The solution with the column installed in front of the vehicle is the classic approach and is aimed at independent workshops, tire chains, and body shops that perform many measurements and require free access to the axle measuring lift.

- With the wall-mounted solution, the customer's needs can be fully met and a tailor-made solution can be offered. For example, the entire camera beam can be mounted above a workbench and seamlessly integrated into the workshop.

In addition to the small space requirement in the workshop, the Q.Lign platform is also characterized by a minimal power requirement. Highly efficient boards in the camera bar replace energy-intensive PCs in the trolley. Even if a workshop were to measure all day, it would save up to 90% of energy compared to conventional PC-based wheel aligners.

Additional information and contact can be found here:

https://www.beissbarth-online.com/en/tseries

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/f/csm_BB_T-series_T41_frontal_b57880f56d.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/4/csm_BB_T-series_T41_QGrip_wallmount_side_97a1d8abf3.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/a/csm_BB_T-Series_T41_Camera_Beam_lift_up_6d0146d3c5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/d/csm_TVA_QL_AC_Clamp_Qgrip_Car_Wheel_TargetBoard_1690101010_1690200002_1baa893f41.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/0/csm_BB_QL_TSeries_SC_Software_Start_09e1c2db21.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/8/csm_BB_QL_TSeries_SC_Software_Measurement_07478a4080.png)